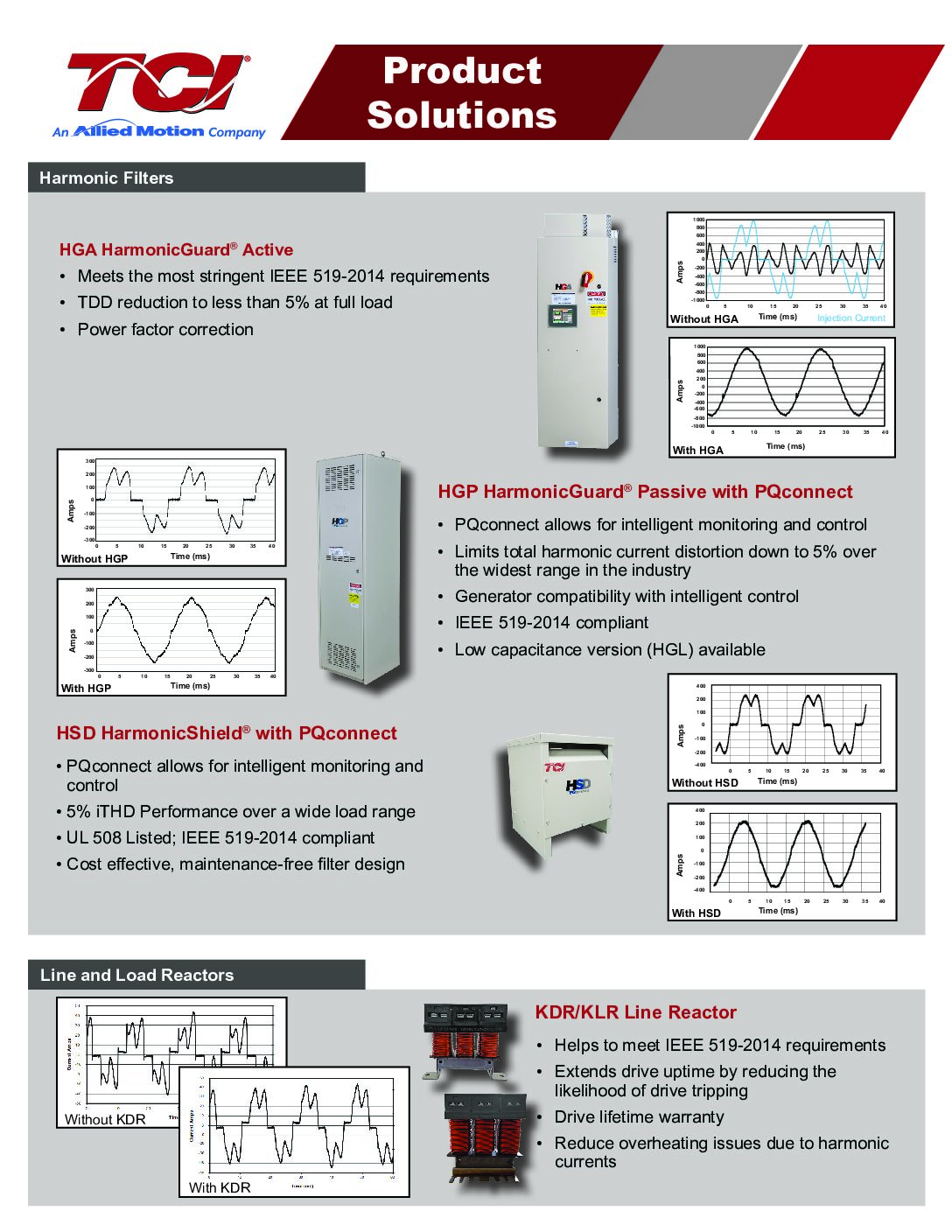

Featured Products

HGA Active Harmonic FilterProblem

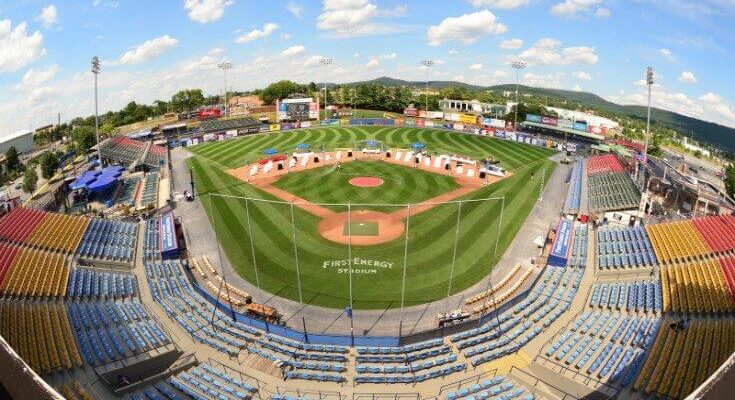

FirstEnergy Stadium, home of the Reading Fightin Phils, unveiled a new player development facility and community center for the 2024 season. The Fightin Phils new Redner’s Event Center will house the home and away team clubhouses, batting cages, weight rooms, female locker rooms, dining areas and kitchens and training room facilities. It also offers a banquet hall that can serve up to 500 guests.

The size of the facility requires some powerful HVAC equipment, which can cause some major harmonics on the grid. During the planning stages of the project, TCI was contacted to assist in mitigating the harmonics before they became a major problem to surrounding neighbors and the power company.

Solution

Two active filters were ordered and put into place: 100 amp and 50 amp HGAs. As a result to adding the two active filters, the Utility company has approved the harmonic limits output from the facility, their sensitive HVAC equipment will continue to run smoothly, and the facility won’t be putting harmful harmonics back onto the power grid affecting neighborhoods surrounding the stadium.