Sine Wave Filter with Connectivity

Without the protection of a sine wave filter, premature equipment failure is caused by the VFD PWM carrier frequency and/or the high dV/dt voltage spikes at the motor terminals.

Using the KMG with PQconnect technology ensures all the high value electrical pumping assets are being protected from failure. The KMG with PQconnect enables pumping and VFD process control adjustments to optimize uptime and prevent power quality issues. Real-time power quality data can be used to monitor and trend for early detection of abnormal conditions.

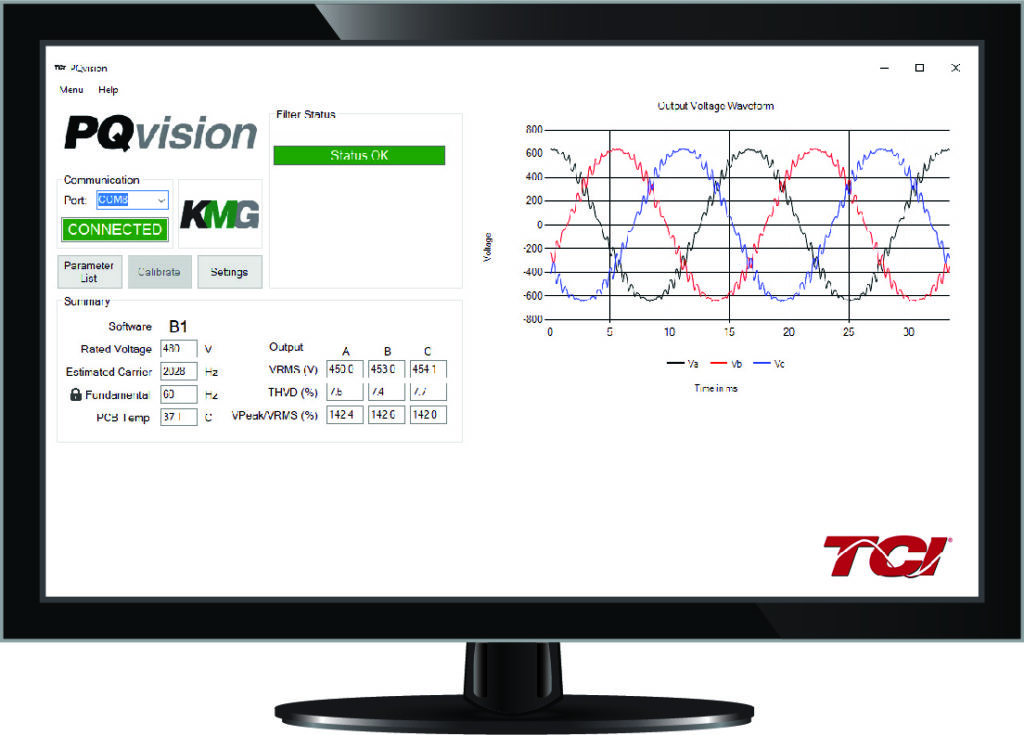

PQvision Software

A free desktop application created by TCI for PQconnect data monitoring.

PQvision software gives you visibility into:

- Real-time filter status detections

- Harmonic voltage distortion alerts

- Filter output voltage wave forms

- Monitor performance through Modbus RTU communications

Use the link below to download the PQvision desktop software.

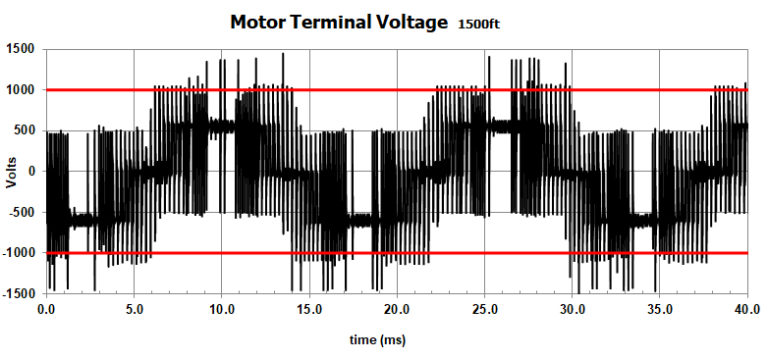

Reflective Wave Phenomenon

Voltage wave reflection is a function of the voltage rise time (dV/dt) and the length of the motor cables. The impedance on either end of the cable run does not match, causing voltage pulses to be reflected back in the direction from which it arrived. As these reflected waves encounter other waves, their values add, causing higher peak voltage. As wire length or carrier frequency increases, the overshoot peak voltage also increases.

Peak Voltages on a 460 V system can reach 1200 to 1600 V, causing rapid breakdown of motor insulation, leading to motor failure. On 575 V systems, the peak voltages can easily reach 2100 V. If this is left uncontrolled, insulation failure may occur. Pulse Width Modulated (PWM) power supplies and Variable Frequency Drives (VFDs) are typically used to improve energy efficiency. However, a major drawback to using PWM power sources and VFDs is that the output is a square wave form, which can cause major motor damage. Critical applications such as HVAC systems and oil field duty require a more sinusoidal output waveform, eliminating these economical and efficient solutions.

Voltage without MotorGuard

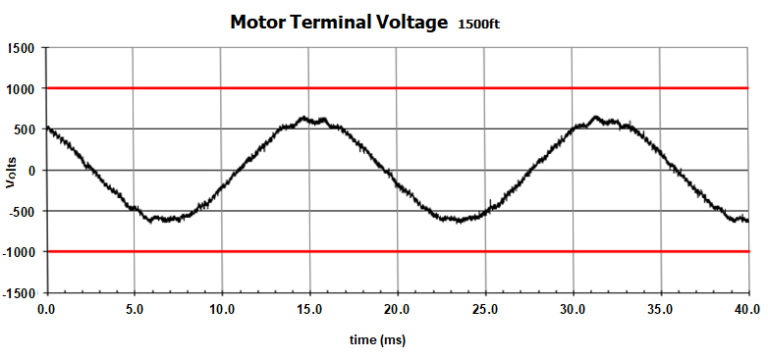

Voltage with MotorGuard

MotorGuard Features

- Less than 5% THVD performance

- Eliminates high dV/dt voltage spikes ensuring optimal motor and cable protection.

- Reduces motor noise, vibration and heat

- Universal acceptance – can be used with virtually all AC induction motors, lead lengths and lead types and used with a wide range of carrier frequencies from 2 kHz to 16 kHz

- Reach long lead lengths up to 15,000 ft. for specific applications

- Modbus RTU communications

- Provides real-time access to waveforms and equipment performance for SCADA systems

- Monitors status of filter components and performance

- Ideal for constant torque applications

MotorGuard Typical Applications

- Long motor lead lengths. Applications can reach 15,000 feet

- Multiple motor applications such as conveyors, blowers, pumps and fans

- Oil and gas pumping systems

- Shore-to-ship power for non-60 Hz systems

- HVAC systems to reduce audible noise

- Low voltage PWM power supply to medium voltage power

For Lighter Variable Torque Applications

For lighter variable torque applications, we recommend the MotorShield Sine Wave Filter.

TCI now offers the MotorShield sine wave filter which provides the same sine wave filter performance as the MotorGuard, but in a smaller package. The MotorShield is the perfect solution for variable torque fan and pump applications.

Performance Guarantee

Properly sized and applied, the addition of a MotorGuard Output Filter is guaranteed to bring the application into compliance with NEMA Standards Publication No. MG-1. If the system fails to meet MG-1 standards with the addition of a MotorGuard filter, TCI will take back the output filter and pay shipping both ways. This offer is valid for 60 days from installation date.

.