PQconnect™ Passive Harmonic Filter Technology Earns ODVA Certification

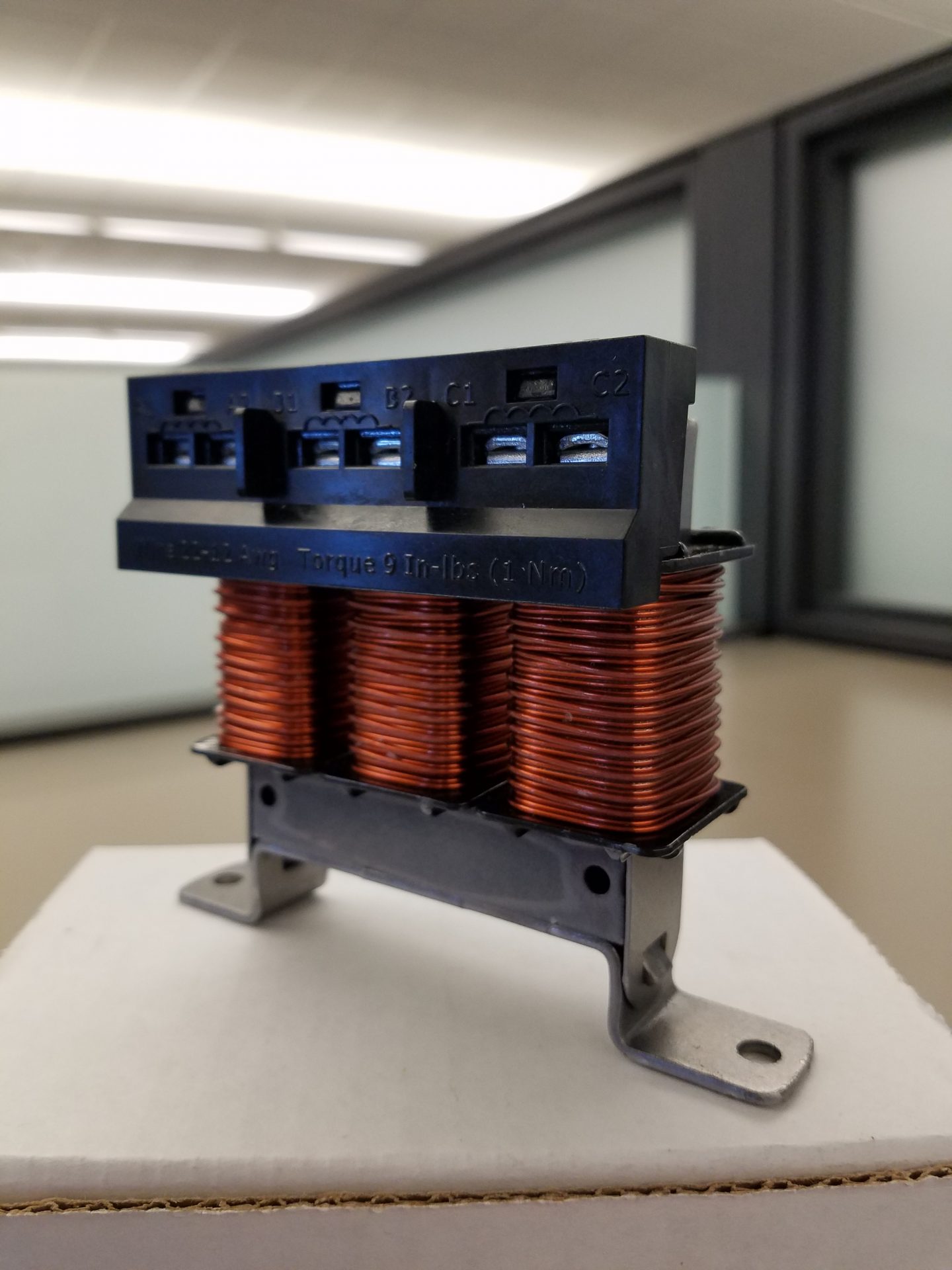

Trans-Coil International, (TCI), an Allied Motion company, announces ODVA certification for its PQconnect™ passive harmonic filter technology platform.

TCI’s PQconnect‑enabled passive harmonic filters now seamlessly integrate into EtherNet/IP® factory automation networks to provide real-time filter status and line parameter data.

PQconnect employs a patented method to measure critical power quality data without the use of separate, expensive current sensors. This allows the same PQconnect hardware to be applied across a wide range of filters (5HP to 1500HP), making the technology highly flexible.

PQconnect converts TCI’s filters into smart devices that can make independent control decisions using the measured data. Furthermore, this data can be shared locally via Bluetooth and to upstream automation systems via various networks, including Modbus and now EtherNet/IP. PQconnect reduces nuisance tripping and downtime, enables automated filter control, provides better drive protection and extends equipment life.

Located in Germantown, WI, TCI is the leading manufacturer of active and passive harmonic filters that mitigate harmonics and improve power quality. TCI’s engineers specialize in developing optimal solutions that achieve IEEE-519 compliance and enhanced motor protection.